Process improvements requires a deep study of its chemistry and physics prior to modify equipment set ups. Usually this kind of studies are not carried out and according the American Institute of Chemical Engineers (AIChe) is the main cause of fatal accidents due to chemical runaways.

Drage & Mate offers the technical service for detailed study of process chemistry and physics, laboratory process simulation in small capacity reactors and pilot plants design for continuous or batch processes.

Our especiality is in the field of Circular Economy, Green Chemistry and Clean Energy:

D&M has qualified personnel to carry out activities of testing:

D&M can provide the service of documentation of existing processes and facilities coming from the on-site review and inspection. Said service may start from any existing information documents or partial documentation and containt as a reference:

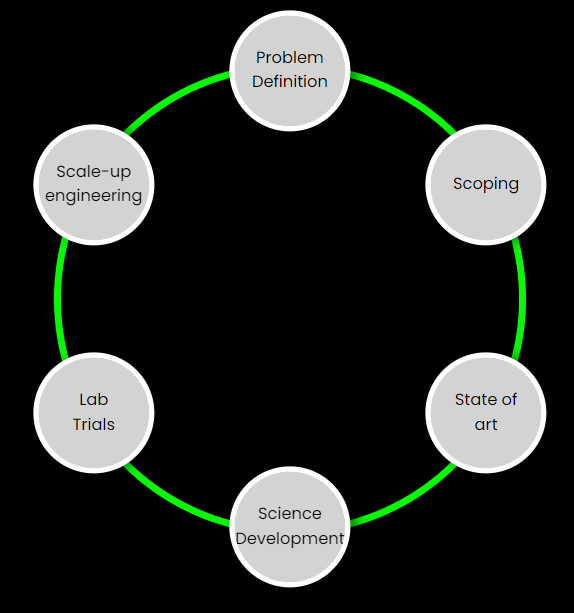

D&M has extensive experience in the industrial scaling-up of processes (starting from its conceptual development or on a laboratory scale). Our complete industrial scaling-up service is developed using our own methodology: QUICUX method. This methodology includes:

If you do not know how to approach a process change, please contact us to discuss options.

Contact us