METALIQ® is specially beneficial for mobility applications where the total weight to be carried is important. The gravimetric energy density of our fuel blends can be up to 10 higher than any battery. So, the weight of Electrical Vehicles (EV) can be reduced significantly.

Our cartridges can be exchanged in the vehicle very fast (in the range of minutes). They are provided by quick connections to minimise the time and effort of the end user.

The solid fuel (alkali and alkali earth metals, boosters, etc…) is contained inside solid state cartridges, which are removed and replaced after depleted. Different universities and NATO safety studies ensure the low risk and easy handle and storage of METALIQ fuels.

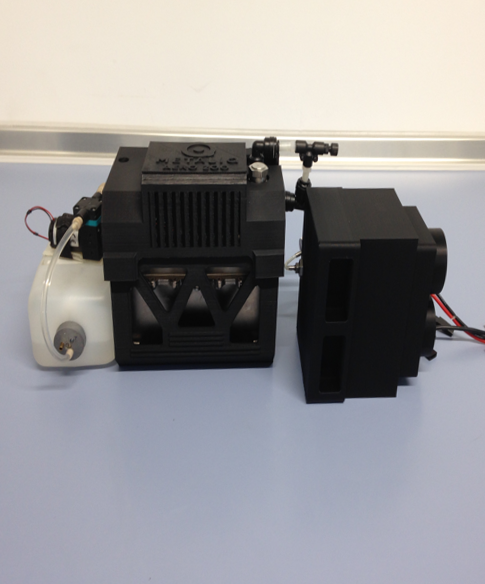

Different applications have been succesfully tested.

Implemented in an UAV (Unmanned Aerial Vehicle). Power: 200W. Energy: 1 kWh.

Energy supply for stationary applications. Power: 500W. Energy: 1 kWh

Energy for mobilephone. Range of mW

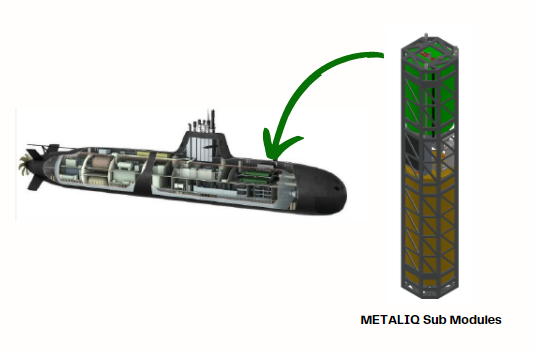

Hydrogen supply to submarines

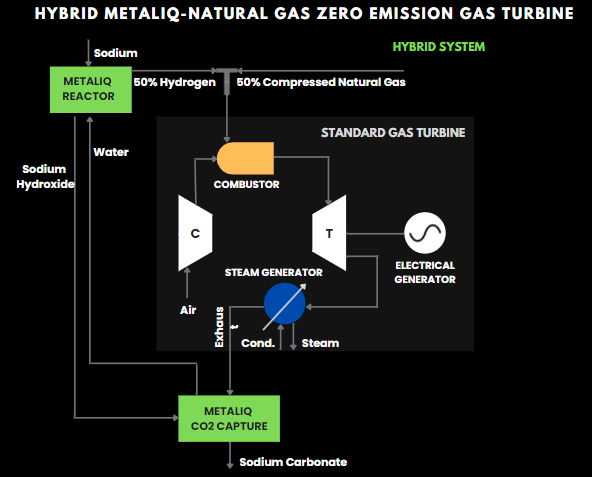

METALIQ® processes can benefit from the direct conversion of existing Natural Gas installation to a ZERO CO2 EMISSIONS. Your business can take advantage of the NG economics thanks to the partial substitution of NG in the burner, kiln, turbine, combustion engine, etc.. for hydrogen.

Our METALIQ® process generate alkali or alkali-earth hydroxides that capture CO2 for the remaining Natural Gas combustion through an absorption process.

The final byproduct of the CO2 auxiliary capture are Green Carbonates used in other industries as raw materials (glass, paper pulp, pharmaceuticals, additives, etc..). Circular economy is an income for the user and a strong benefit for the Society.

«METALIQ® allows you reach ZERO CO2 EMISSIONS while continuing using fossil fuels such as natural gas. There is not other technology capable to offer such economical/environmental balance».

Benefit from the unique features of METALIQ technology and get ahead in your business.

Contact us